Cincinnati Companies Come Together to Create a New Look

by Tyler M. Secor

A prototype of the new Pops jacket hanging on a mannequin inside the Sew Valley factory. Credit: Tyler Secor

A prototype of the new Pops jacket hanging on a mannequin inside the Sew Valley factory. Credit: Tyler Secor

Before taking the stage for the first Cincinnati Pops concert in 1977, the musicians would have donned their red jackets. Thick polyester jackets. Under the intense lights of the stage. Playing a two-hour, or longer, concert. HOT and uncomfortable!

The red jackets of the Cincinnati Pops are, by now, iconic. Created with the founding of the Cincinnati Pops in 1977, the red jackets have been an ever-present part of the Pops concert experience. Over the decades, the red color has remained the same, but the actual jackets have changed due to style updates, fabric choice and wear.

The current jackets have been in use for more than a decade, and the cut of them has fallen out of fashion.

“I was just given the closest size there was when I joined the Orchestra a few years ago,” recalls Emily Beare, who plays oboe in the Orchestra. “It was not tailored to me specifically. It’s quite big and doesn’t fit well. It’s not breathable. It’s not very flexible. I guess it is durable, because it’s old and it’s lasted quite a while.”

It was time for an update. But how? Open up a catalog, select red and order? Or design something new that meets the unique needs of orchestral musicians?

The Pops chose option two, tapping Amber Ostaszewski, director of audience engagement—and, as luck would have it, an expert in textiles and fiber crafts—to lead the “New Pops Jackets Project.” They issued a Request for Proposals (RFP) to tailors and garment houses in early 2019, with a plan to have new jackets on stage for the opening of the 2019–20 season.

Ostaszewski recalls one tailor whose RFP response was “It can’t be done!” But one willing partner stood out. It wasn’t a fashion house or factory from New York or Los Angeles. Instead, the winning proposal was a non-profit garment factory in Cincinnati, one mile from Music Hall—Sew Valley.

Located underneath The National Flag Company in the West End, Sew Valley is a sustainably focused garment factory, sample room and incubator space that exists to help apparel entrepreneurs and brands manufacture locally, sustainably, ethically and efficiently.

The commercial apparel industry is notorious for its dangerous working conditions, extremely low wages, astonishing amounts of waste and negative environmental impact. A few examples of the industry’s impact: factories use 13-inch exposed cutting blades to slice through stacks of fabric, they use harsh dyes and chemicals, and they produce more than two billion tons of greenhouse gas emissions each year.

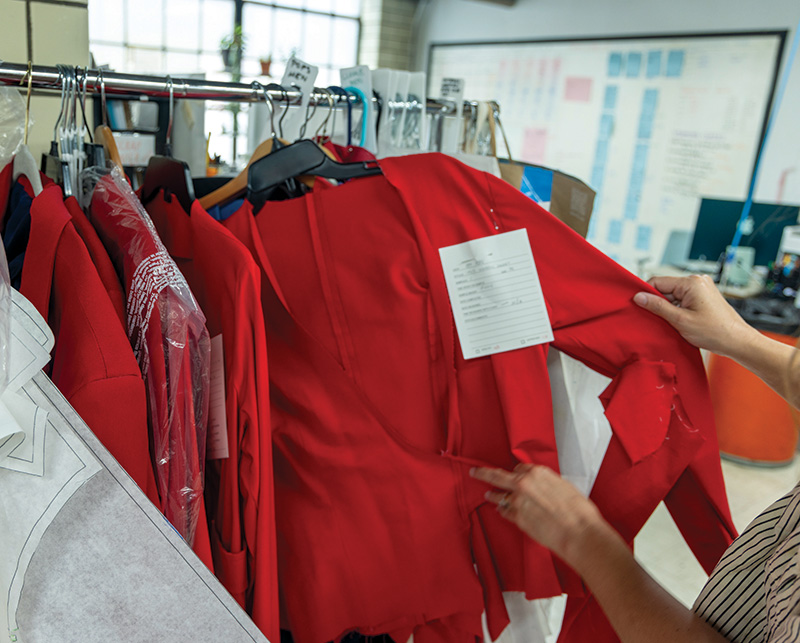

A rack holding different design mock-ups for the new jackets. Credit: Tyler Secor

A rack holding different design mock-ups for the new jackets. Credit: Tyler Secor

In contrast, Sew Valley seeks to change the way apparel is manufactured and create a sustainable future for “ourselves individually, our community, the brands we work with and the planet.” The apparel industry literally touches each of us, and, right here in Cincinnati, Sew Valley is leading the charge toward better, safer manufacturing practices.

With the proposal accepted, two Cincinnati companies—an orchestra and a garment factory—formed a partnership and set out to create a new look for the Cincinnati Pops.

“I thought it was a great opportunity to improve the performance and lives of the musicians,” remarked Rosie Kovacs, co-founder of Sew Valley, “through something as subtle as a jacket.”

Before prototype designs could be built and toiles (fabric mock-ups) created, the designers at Sew Valley needed to determine a median size. They measured each orchestra member and calculated the median from those measurements.

Now the design and sampling process could begin.

The inside pocket adorned with the Cincinnati Pops logo. Credit: Tyler Secor

The inside pocket adorned with the Cincinnati Pops logo. Credit: Tyler Secor

Fanfare Magazine spoke with Shailah Maynard, co-founder and CEO; Madeline Misleh, director of operations; and Aubrey Krekeler, director of operations at the Sew Valley factory, amid the whir of industrial sewing machines, large cutting tables, and the laughter of team members working on their latest projects.

“We did make a couple of samples that were like, no, this isn’t going to work,” remembers Maynard. “It was just too big of a change.”

“We had gone from full-blown athlete-inspired, while still looking clean and minimal,” recalls Krekeler, “to something in between—a bit more traditional, but the jacket needs to function like athletic wear.”

“In the beginning, we played with a lot of different fabrics,” explains Krekeler.

“We needed a fabric that appears like traditional suiting,” Misleh, who comes from a family of tailors, describes, “but it’s got to have a lot of stretch, have more capabilities for someone moving on stage and be breathable.”

In the end, the Pops and Sew Valley landed on two designs: a jacket that looks more like a traditional suit coat (called the “long style”) and a shorter wrap style jacket (called the “short style”). The look on the outside is important, but it’s the unseen that really makes these jackets special and unique for musicians performing on stage.

Inside of the new jackets showing the minimal lining, which helps to reduce bulk and weight and increase breathability. Credit: Tyler Secor

Inside of the new jackets showing the minimal lining, which helps to reduce bulk and weight and increase breathability. Credit: Tyler Secor

We started from a traditional pattern and modified it from there,” states Misleh. “We played with shoulder seam placement and how much stabilizer to use in certain places.”

A traditional suit coat has many layers of fabric fused with interfacing or stabilizer to give the garment structure, but more layers mean a heavier and hotter garment. Therefore, the Sew Valley team created a jacket with limited layers of fabric and interfacing to make the jackets light and breathable.

Sew Valley was responsible only for creating the jackets, but they had to consider the entire outfit. What type of shirt would the musicians wear? How could that impact the jacket design?

For example, each jacket is only half lined for breathability, and the sleeves are, for the long style, unlined to be worn more comfortably over a long-sleeve, button-down shirt, and, for the short style, lined, to be worn over a sleeveless blouse.

Sew Valley’s Aubrey Krekeler sewing a sleeve seam on a new jacket. Credit: Tyler Secor

Sew Valley’s Aubrey Krekeler sewing a sleeve seam on a new jacket. Credit: Tyler Secor

Instrument placement was also considered. The long style has a smaller width collar than traditional jackets to accommodate the placement of a violin or viola. The short style has no collar. And extra room was added to the shoulders of both lengths to accommodate the arm and hand positions of musicians who have to hold their instruments up.

Longevity of the garment was also important. The seam allowances are wider and the seams easier to access, “so you don’t have to totally take apart the jacket to alter those seams,” explains Misleh.

With the fabric chosen and designs locked, the next step is called a “size run.”

“Producing these jackets in house just wasn’t going to be an option,” remarked Misleh, “because producing tailored jackets is not something we do in bulk at the Sew Valley factory.”

Luckily, a trusted contact of Maynard’s out of New York agreed to complete the production of the 150 or so jackets. The New York-based garment factory refined the pattern for mass production and completed the grading (i.e., from the base pattern, creating all of the various sizes). Then the factory made one jacket in each size.

During the 2023–24 season, each musician tried on a jacket and chose their size and style. From there the full run of jackets was created in New York.

By the final weeks of the 2023–24 season, the wardrobe room at Music Hall was a sea of red jackets ready for fittings and alterations. Sew Valley tailored each jacket to match each of the nearly 100 musicians.

Sew Valley’s Heidi Johnson finishes a cuff alteration with a series of hand stitches to reattach the lining. Credit: Tyler Secor

Sew Valley’s Heidi Johnson finishes a cuff alteration with a series of hand stitches to reattach the lining. Credit: Tyler Secor

And now the five-year project comes to fruition as the musicians of the Cincinnati Pops don their new, bright red Sew Valley jackets and take to the Music Hall stage September 13–15 for Rick Steves’ Europe: A Symphonic Journey. Looking on from the audience will be the Sew Valley team, who, for the first time, will get to see their jackets en masse in their intended milieu—the result of a partnership that embodies Cincinnati’s motto: Juncta Juvant, meaning “strength in unity” or “united they aid each other.”

“I know we all appreciate the consideration it took to pick these for us,” states Rebecca Pancner, who plays piccolo in the Orchestra. “It’s a privilege for us to have jackets made in a sustainable way. We’re very fortunate that we have enough funding and support from the community to go in a direction that really fits with our values.”

Behind the scenes of the style guide photoshoot where models were photographed to demonstrate the correct wearing and styling of the new jackets. Credit: Tyler Secor

Behind the scenes of the style guide photoshoot where models were photographed to demonstrate the correct wearing and styling of the new jackets. Credit: Tyler Secor

Be sure to visit the Founder’s Room during the concerts on September 13–15 to see the new Pops jackets up close and look through the various photos and samples of the entire process.